Goal: To design and create a new kitchen tool based on information gained through user research.

Initially, I interviewed people with varied backgrounds in cooking. From that data, a new tool was conceptualized, designed, prototyped, and ultimately fabricated.

My project was based on improving a standard rubber spatula. By having removable heads and double ends, the spatula can fill roles of many tools, while taking up a fraction of the space in a cabinet.

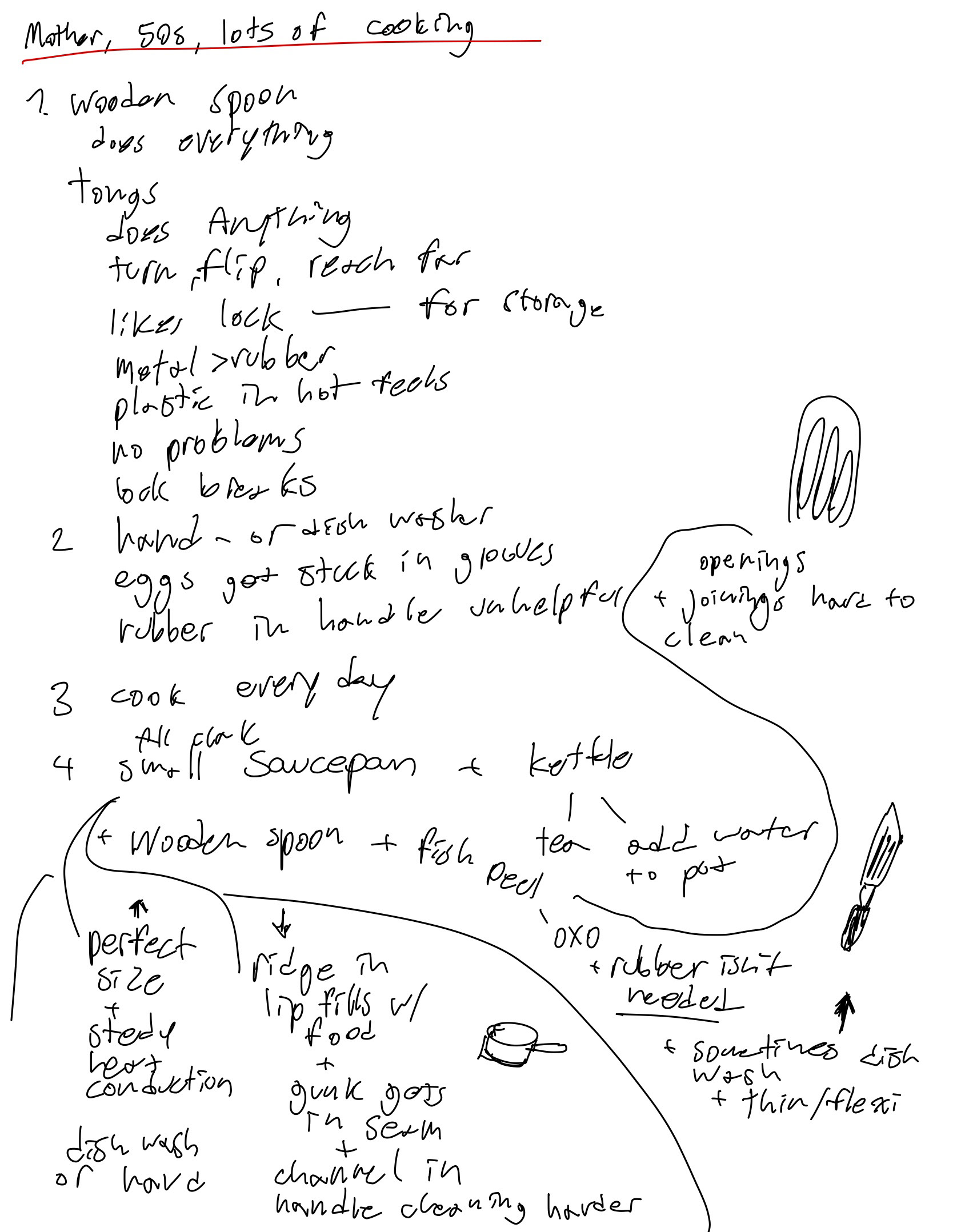

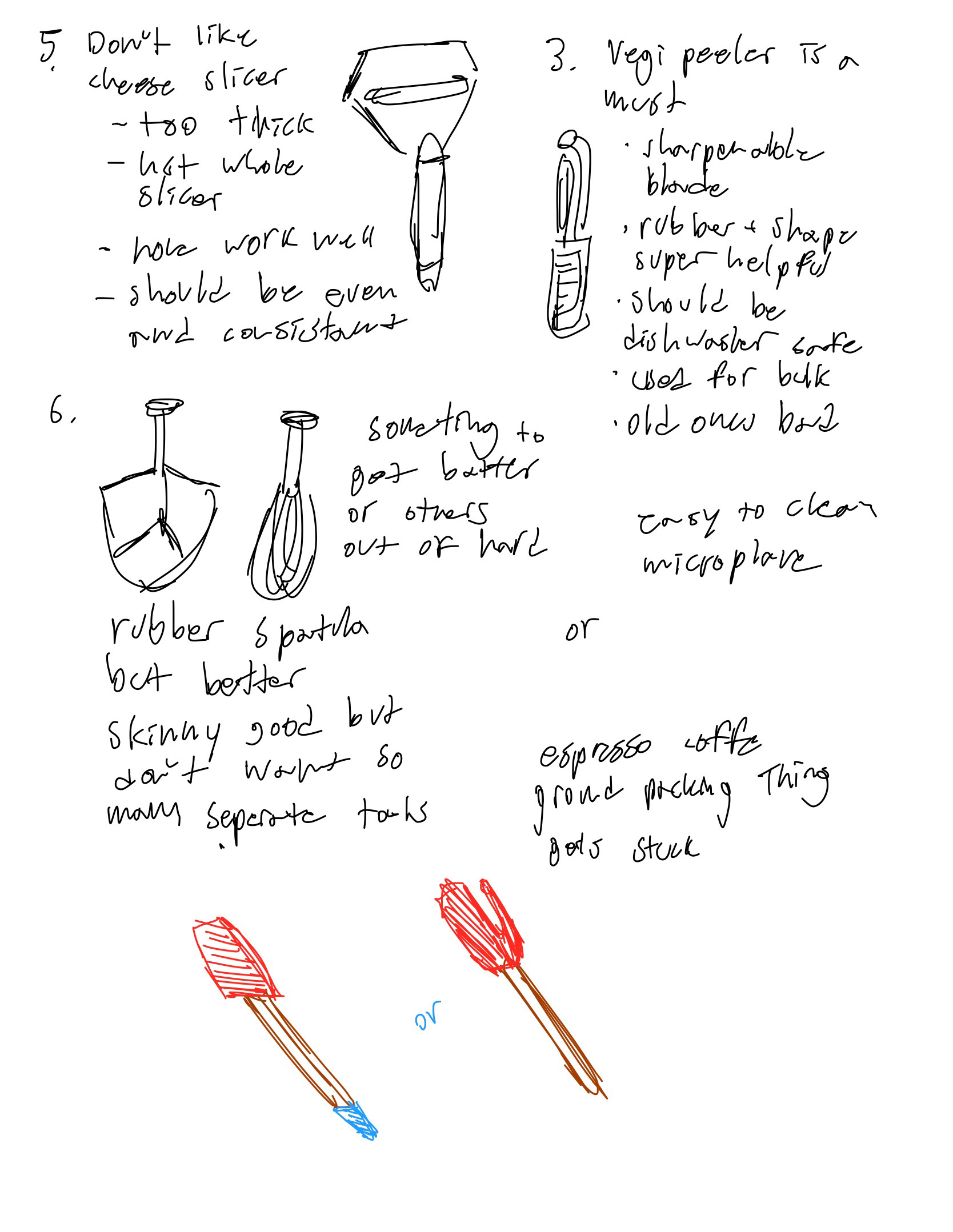

Interview Notes

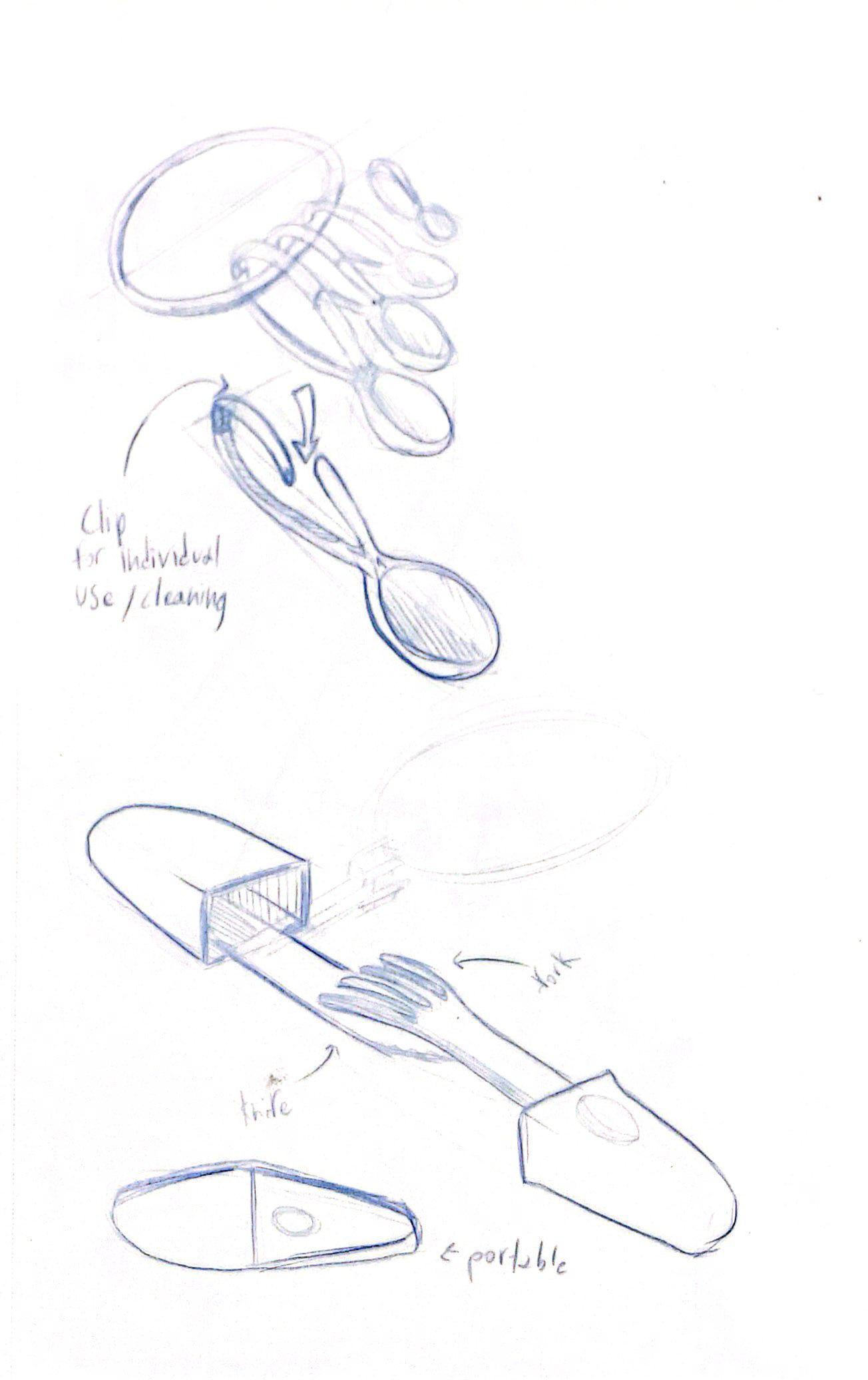

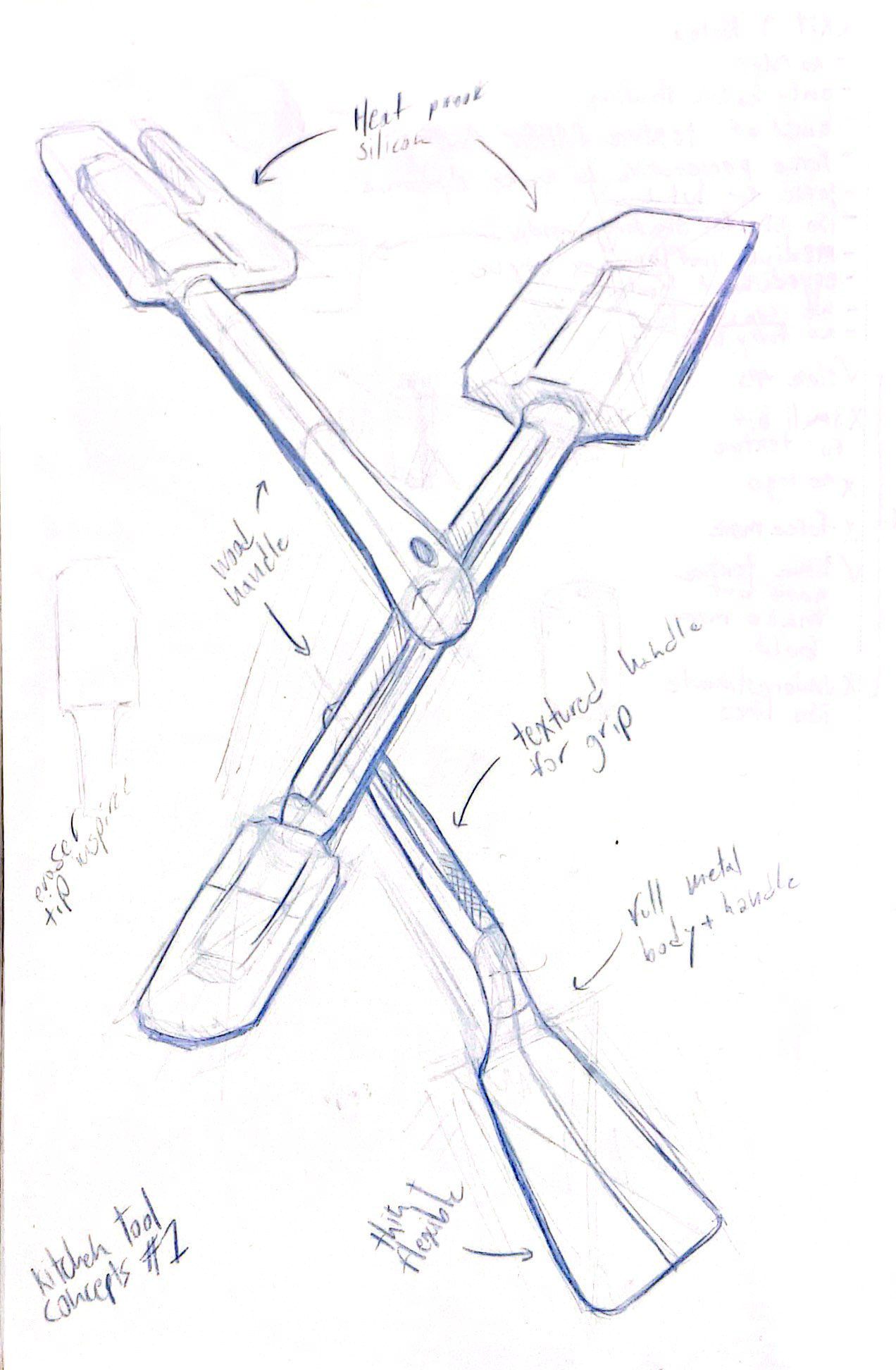

Concept Generation

I used key points from my research, combined with my own cooking experience to come up with concepts for new kitchen tools.

I wanted to avoid overly complicated or gimmicky ideas. I find that the best kitchen tools are those that are simple and versatile, which was reflected in my interviews.

Finalized Concept

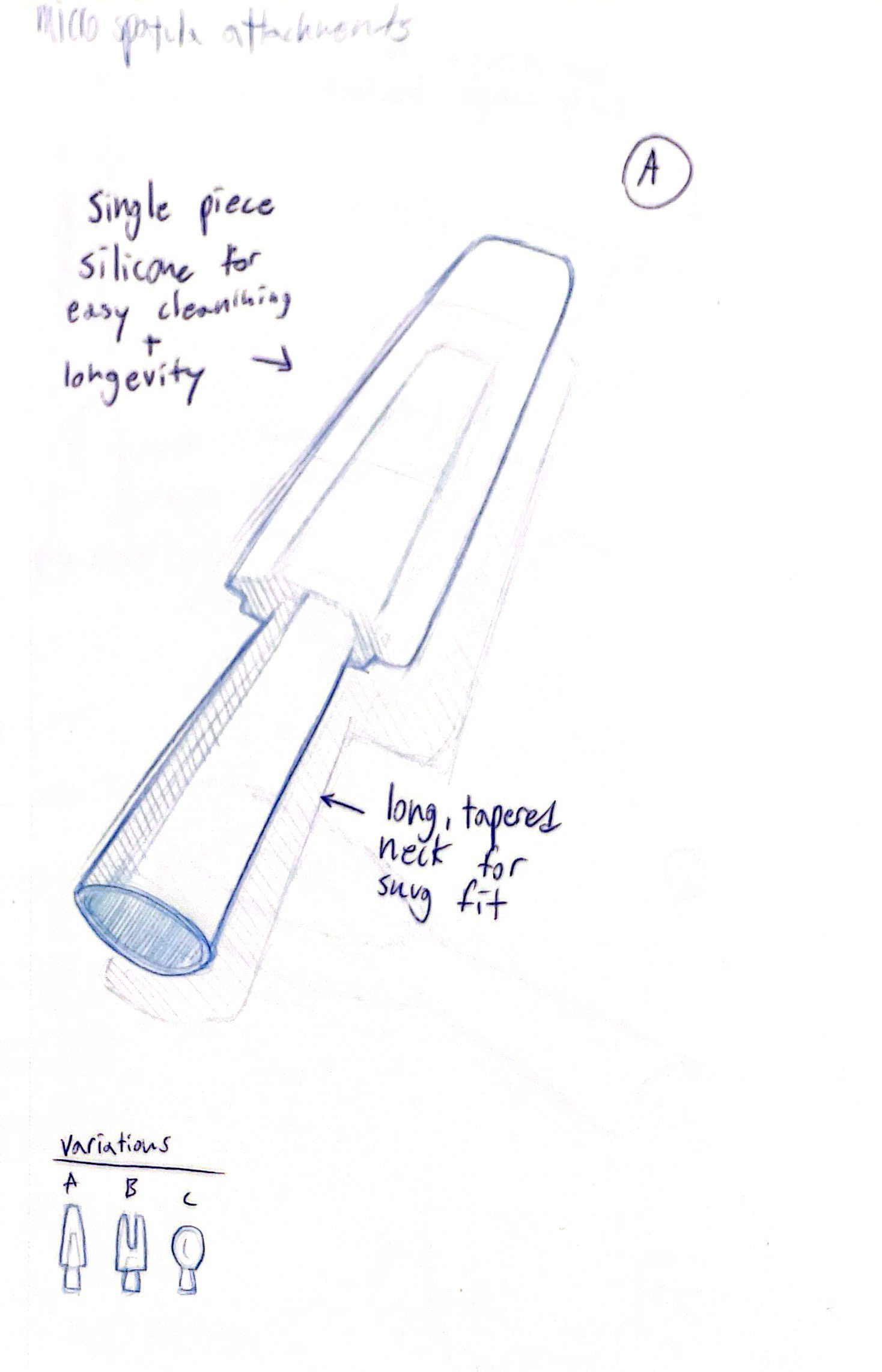

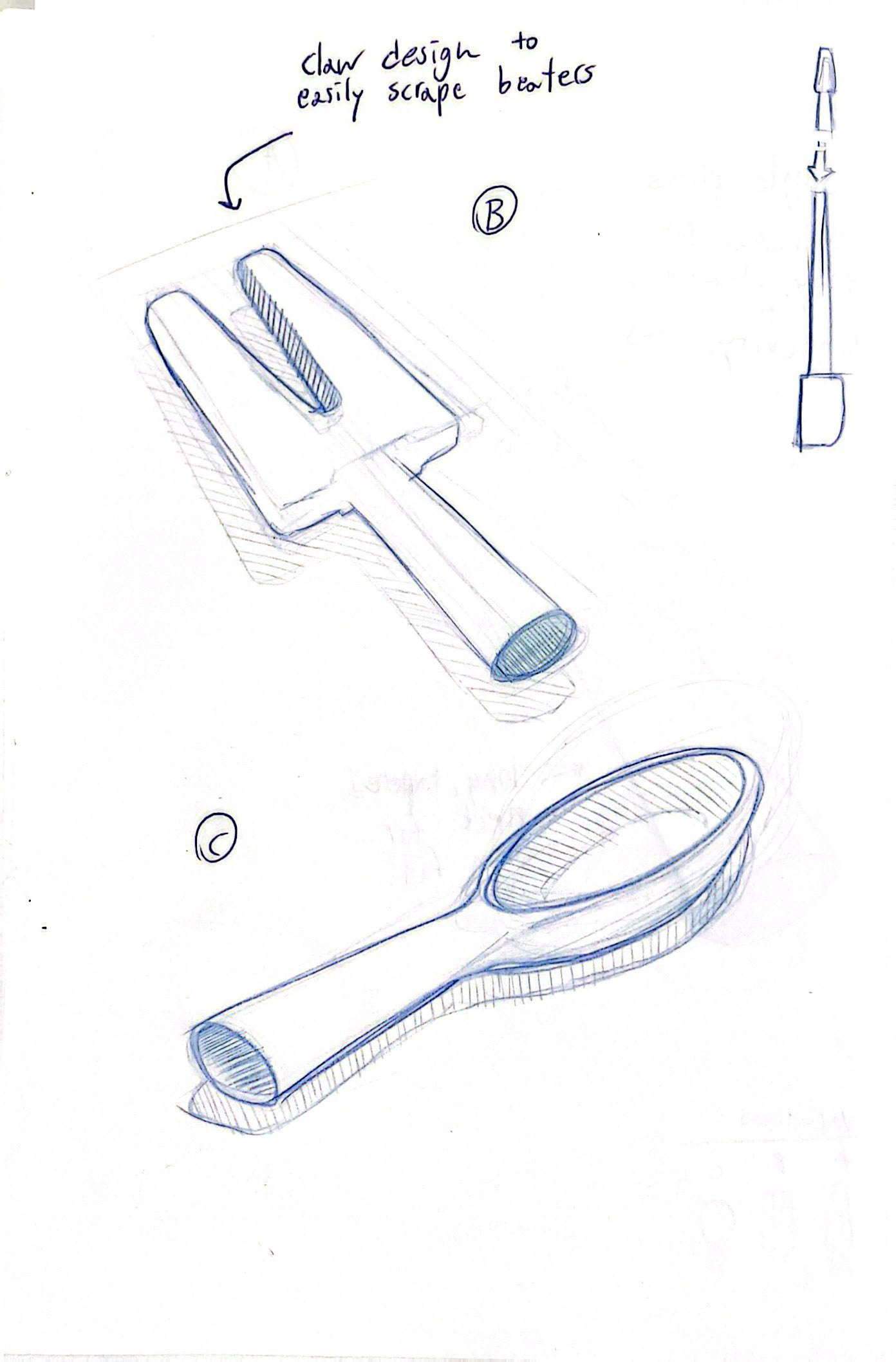

Based on feedback received during critique, I combined my favorite two ideas: a spatula with a small, precision head on the opposite side and a lobster claw shaped spatula for scraping off a mixer attachment.

I planned to create a customizable spatula system, with a comfortable double sided handle and numerous heads. Similar to how pencil eraser caps function. The multi-head design takes up less space in the drawers, and allows users to customize the tool to suit their needs.

Plasticine Model

I decided to make 3 different attachments: an extra large head for mixing large batches, a precision head for spreading on smaller surfaces (cookies, cupcakes, etc.) and a lobster claw head for scraping off beater attachments.

I made series of plasticine models to visualize size and shape of each attachment, and also made a handle out of cardboard and tape to test length and thickness.

Prototyping

I modeled each attachment in CAD software, then printed positives to see what the objects would look and feel like. Next, I designed an interlocking three part mold and used wax to test it.

The wax did not properly release from the mold, but still taught me where I had gone wrong: I needed to print the molds vertically, then sand them to reduce visible layer lines, and I needed to reduce material as printing this initial mold was both time consuming and wasteful. I also needed to redesign the handle insert piece, as it wasn't sitting completely flat due to the edges of the main mold warping.

I tested multiple different handle diameters and shapes by having people with varied hand sizes hold prototypes and imitate mixing and spreading motions. I decided upon a handle that tapered a quarter inch in both directions, and was flat along opposite sides so the user can orient the spatula in their hands without looking.

Mold Redesign

I redesigned the mold to reduce material by making it conform to the inner shape, and by making the base as a separate piece. I also redesigned the handle insert to allow it to sit level on the mold.

To prep the molds I sanded them thoroughly, sprayed them with multiple coats of filler primer, then sanded them more.

Pouring

I did a lot of research to find the right material for this project. I needed the spatula to be food safe, heat resistant, and somewhat flexible as an overly floppy spatula becomes almost useless. My findings led me to only one option: Smooth-Sil 960.

I prepared the molds by screwing both ends together with m3 screws, then compressing the insert using rubber bands. I measured and mixed the silicone using a gram scale, and poured it on top of my washing machine while it was running, as vibrations helped reduce bubbles.

Final Steps

After curing for 16 hours, I was able to de-mold each attachment. I trimmed the excess off with a razor blade, and was left with three mostly seamless spatula heads.

I completed the handle and sanded it up to 800 grit, then finished it in a coating of tung oil for food safety and moisture resistance.

Conclusion

Though there are minor flaws in the final products (slight bubbling, softer than intended), I still am quite happy with the result. The process taught me a lot about working with new materials and the importance of thorough prototyping.

To accompany this project, I created a video that satirically imitates a basic TV commercial from when I was a kid. I think it highlights the strengths of the product nicely in a fun way.